The "MasterScaling" input is ignored since the master length of the cam is calculated by multiplying the current master speed by the "CamTime". In this mode, the relationship between "MasterScaling" and "SlaveScaling" changes automatically so that the slave speed remains constant even when the master speed changes. The master/slave interval always remains constant, i.e. at the configured values.

This is important for a cross-cutter where the blade turns perpendicular to the material, for example.

N10008 |

MasterLength = CamTime x Master speed |

Application example

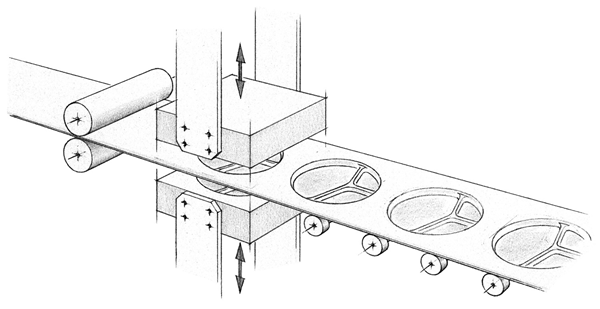

Thermoforming

A heated tool is used to stamp a shape in sheet of plastic while the sheet is stationary. The temperature of the tool is regulated to a defined value, and the duration of the stamping process is constant. The master and slave intervals are predefined.

For this reason, only the feed movement can be varied with a changing line speed. The feed movement is varied automatically in this mode.

Information:

•A normalized cam (master and slave length = 1) should be used since the master factor is calculated automatically based on the master speed, making it possible to achieve a higher resolution.

•When the master speed changes, a number of parameters are calculated and transferred to the drive. Depending on the master speed, it may take a number of intervals until the actual cam duration matches the one that is set.