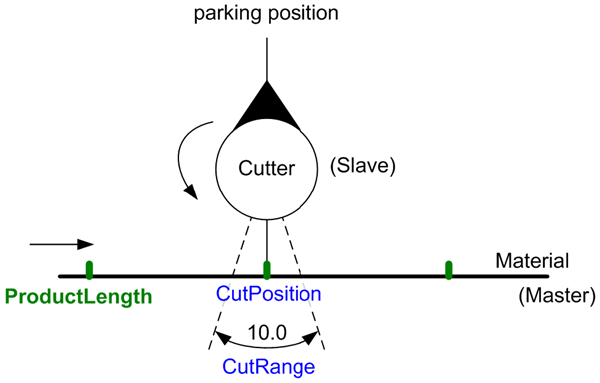

The distance from the current parking position to the "CutPosition" is calculated for the first movement (synchronization). The recurring cutting movement takes place from "CutPosition" to "CutPosition" using the specified PLCopen period while the master covers the distance from "ProductLength" + "ProductLengthCorrection" (see states 2 and 5 of the Cam Profile Automat).

"CutRangeMaster" and "CutRangeSlave" define the area where the blade has contact with the material. "CutPosition" represents the middle with respect to "CutRangeSlave". The cross cutter moves synchronously to the master axis within this range. A faster or slower movement can be configured using the "CutOverspeed" parameter in the "AdvancedParameters".

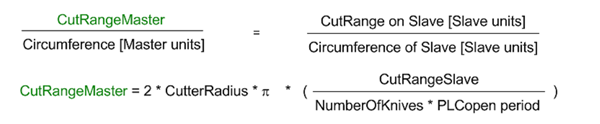

If the value "0" is entered for "CutRangeMaster", then the values for "CutterRadius" and "NumberOfKnives" must be entered under "AdvancedParameters". The following formula is used for the calculation:

Example with one blade

Axis units per revolution: 10000

PLCopen period: 10000, Factor 100

Distance traversed within one product length: 100.0 PLCopen units

CutPosition: 0.0

CutRangeSlave: 10.0

Information:

The parking position should be outside of the cutting range ("CutRangeSlave")!

StartMode = mcMASTER_POSITION |

StartMode = mcIMMEDIATE |

AdvancedParameters.FirstCutPosition = 0.0 |

AdvancedParameters.MasterStartDistance = 0.0 |

AdvancedParameters.MasterStartDistance = 0.0 |

|

Example with two blades

Axis units per revolution: 10000

PLCopen period: 5000, Factor 100

Distance traversed within one product length: 50.0 PLCopen units

CutPosition: 0.0

CutRangeSlave: 10.0