This function block initializes a Cam Profile Automat on the drive that can be used to control a cross cutter.

The "ProductLength" and "ProductLengthCorrection" inputs can also be used to perform registration mark correction without having to use MC_BR_Phasing.

The distance between two blades is specified using the configured PLCopen period of the slave axis. This can be defined either in the NC mapping table or with the MC_BR_InitModPos function block.

Requirements for use

•This function block can only be used on SG4 target system.

•This function block cannot be used with axes on a CAN bus.

•The distance from blade to blade must be defined as a PLCopen period for the slave axis!

•"CutPosition" and "CutRangeSlave" must be within the PLCopen period of the slave axis!

•"CutRangeMaster" must be within the "ProductLength"!

•If the slave axis is corrected (e.g. with MC_BR_Offset), then the cutting point is shifted as a result!

•The master axis is only permitted to move in the positive direction!

•Axis states of the slave axis in which this function block can be used:

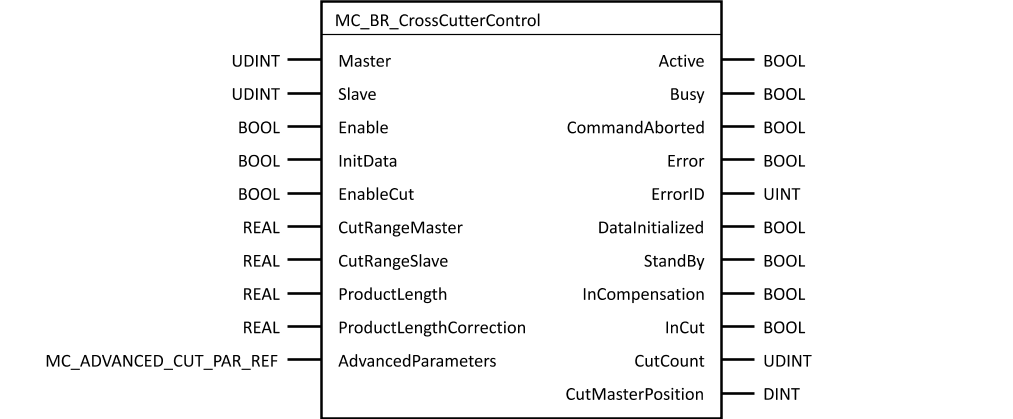

Function block

Parameter

I/O |

Parameter |

Data type |

Description |

IN |

Master |

UDINT |

Master axis reference |

IN |

Slave |

UDINT |

Slave axis reference |

IN |

BOOL |

The function block is active as long as this input is set. |

|

IN |

InitData |

BOOL |

Initializes input data on a rising edge (online change of function block input data) |

IN |

EnableCut |

BOOL |

While this input is TRUE, the cross cutter is moving in accordance with the function block configuration. The movement can be paused and continued with this input as long as the "Active" output is set. |

IN |

CutRangeMaster |

REAL |

Cutting area of master axis within which the cross cutter ("slave") should run synchronously to the "master" [PLCopen units of master] Note: This value can be set to "0" if "CutterRadius" and "NumberOfKnives" are defined in "AdvancedParameters". |

IN |

CutRangeSlave |

REAL |

Cutting area of slave axis within which the cross cutter ("slave") should run synchronously to the "master" [PLCopen units of slave] Note: "AdvancedParameters.CutPosition" is in the middle of "CutRangeSlave". |

IN |

ProductLength |

REAL |

Distance between two cuts (product cycle) [PLCopen units of master] Note: This value can be changed in each product cycle with "InitData". |

IN |

ProductLengthCorrection |

REAL |

This value is added to the "ProductLength" input before "ProductLength" is transferred to the drive. This makes it possible to correct a cut using a value determined from a higher-level registration mark control process. [PLCopen units of master] Note: The "InitData" input takes on this value for one product cycle following each rising edge. This value is only used in cyclic cutting or when changing the "CutPosition (see Cam Profile Automat description). |

IN |

AdvancedParameters |

MC_ADVANCED_CUT_PAR_REF |

Additional input parameters for optional use with the function block. |

OUT |

Active |

BOOL |

Function block active, possible to execute movements Ready for "EnableCut" |

OUT |

Busy |

BOOL |

The function block is active and must continue to be called. |

OUT |

CommandAborted |

BOOL |

Function block aborted by another function block |

OUT |

Error |

BOOL |

Error during execution |

OUT |

ErrorID |

UINT |

|

OUT |

DataInitialized |

BOOL |

Parameter transfer started with "InitData = TRUE" completed |

OUT |

StandBy |

BOOL |

The movement can be resumed from the last position with "AdvancedParameters.StartMode" = mcRESTART. |

OUT |

InCompensation |

BOOL |

Indicates that the slave is carrying out a compensating movement |

OUT |

InCut |

BOOL |

Indicates that the slave is within the cutting area |

OUT |

CutCount |

UDINT |

Number of cuts carried out since the function block was enabled |

OUT |

CutMasterPosition |

DINT |

Frozen value of the master axis whenever the blade cuts the material at the cutting position (can also be used for registration mark control) [Axis units of the master] |

Table: Parameter MC_BR_CrossCutterControl

MC_ADVANCED_CUT_PAR_REF data type

Parameter |

Data type |

Description |

CutOverspeed |

INT |

Reduces or increases the cross cutter speed within "CutRange" [%] Note: Only values greater than "-50" are permitted! Note: -50% … Slave runs at half speed in relation to the master axis 0% … No synchronization, slave runs at the same speed as the master axis 100% ... Slave runs at twice the speed of the master axis |

CutterRadius |

REAL |

Specifies the radius of the cross cutter used to calculate "CutRangeMaster" in relation to the circumference of the slave [PLCopen units of master] Note: This value is needed if "CutRangeMaster" is not specified. |

NumberOfKnives |

USINT |

Number of blades along the slave circumference whose interval corresponds to the PLCopen period Note: This value is needed if "CutRangeMaster" is not specified. |

StartMode |

UINT |

Mode for the initial movement after the function block is enabled The following values are possible: mcIMMEDIATE ... 0 mcMASTER_POSITION ... 256 mcRESTART ... 273

In addition, the following additive mode is available in V2.370 and higher: +mcCORRECT_CURRENT_CYCLE ... 32768 |

CutPosition |

REAL |

Absolute cut position within the PLCopen period [PLCopen units of slave] Note: Default value: 0.0 This input value can be used to shift the cut position within a slave period. |

FirstCutPosition |

REAL |

Position within the master axis period or absolute position for a non-periodic master axis where the first cut should take place [PLCopen units of master] Note: For an immediate start, see "AdvancedParameters.StartMode". |

StartInterval |

REAL |

Interval for generating a starting event (a multiple of "StartInterval" is added to "FirstCutPosition" so that the movement can be started in synchronization) [PLCopen units of master] Note: If "0.0" is specified, then "ProductLength" is used. For an immediate start, see "AdvancedParameters.StartMode". |

MasterStartDistance |

REAL |

Distance of the master axis in which the cross cutter should be synchronized to the first cut position [PLCopen units of master] Note: If "0.0" is specified, then half of the "ProductLength" is used. This value is used after "EnableCut" = TRUE (see Cam Profile Automat State1) |

CamTableID |

USINT |

ID number of the cam (e.g. output from MC_CamTableSelect) A specific cam can be used to carry out special cutting movements, e.g. push-out motions. Note: The cam should be normalized to master and slave length = 1 in order to take advantage of the "CutOverspeed" parameter. If mcLINEAR_CAM or 0 is specified, then a predefined 1:1 cam is used. If a cam is used, e.g. for a push-out motion, specifying a value for "CutOverSpeed" that results in a slope within the cam ≥"1" is recommended. This prevents buckling of the product. |

MasterParID |

UINT |

This ParID is used instead of the position setpoint; 0…Use position setpoint Note: When using a value other than 0 (even if the position ParID), the PLCopen factor of the master axis is not applied to any of the parameters involving the master axis. |

MasterMaxVelocity |

REAL |

If a value is simultaneously specified for "MasterParID": Maximum velocity of MasterParID value

If a value is not specified for "MasterParID": Maximum velocity of the master axis [PLCopen units of master/s] If this parameter is "0.0", then the current velocity of the master axis at the time of the rising edge of the "Enable" or "InitData" input is used. Note: This value is used to calculate the compensating movement for coupling, changing the gear ratio or cams as well as between the cutting areas (depending on the function). This parameter has a considerable effect on the occurrence of ACOPOS error 37113: "Cam compensation gear: Limit values exceeded". No value specified: A master speed that changes or a parameter update via "InitData" or "Execute" can result in different, automatically calculated motion profiles. Value specified: Specifying the maximum speed value of the master axis that is achieved while coupled to the slave axis results in a motion profile that is always automatically calculated the same. |

Topics in this section: