In this mode, the synchronous cam - compensating movement (transition) sequence is repeated cyclically.

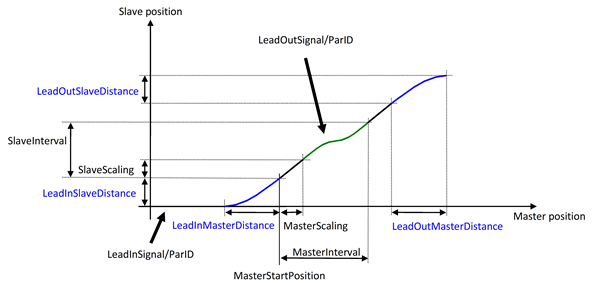

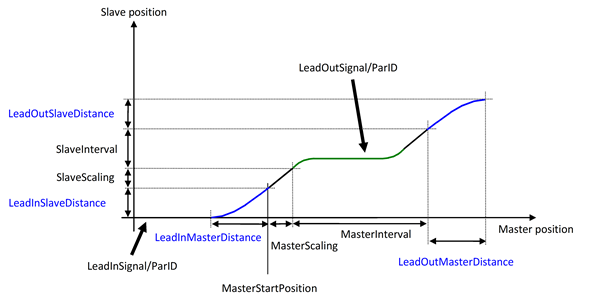

After the lead-in signal is set, the lead-in movement is performed once before switching to the synchronous cam.

If mcLEAD_IN is not enabled, the system switches directly from standstill to the sync cam.

After setting the lead-out signal, the lead-out movement is performed once after the sync cam and ends with the standstill of the slave axis.

If mcLEAD_OUT is not enabled, the system switches directly to standstill from the sync cam.

After the lead-in signal is set again, the sequence begins the next time the "MasterStartPosition" is reached.

A long master interval and a short slave interval causes the slave to reach a standstill during the transition.

Application example

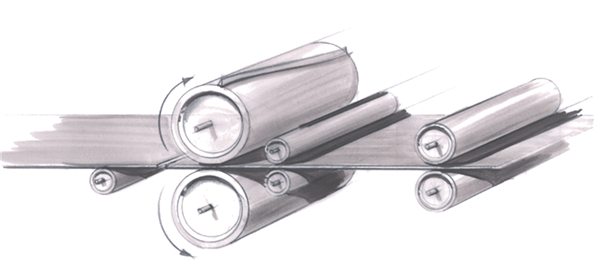

Cross cutter

A cylinder with a tool makes contact with the product moving beneath it as it rotates. During this contact the movements must be synchronized. A defined master length must be allowed to pass between each processing step. Even when the line speed varies, the specified master length and synchronization must be maintained.

Information:

The sum of "LeadInSlaveDistance", "LeadOutSlaveDistance" and the slave curve length should equal the "SlaveInterval"; otherwise, the waiting position of the slave is shifted.