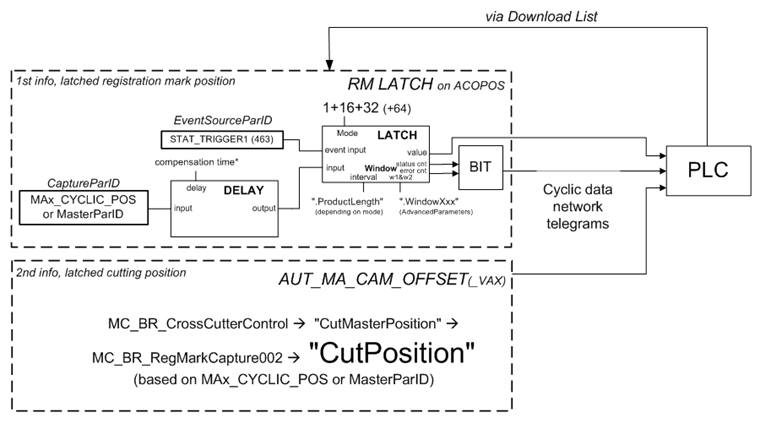

An absolute deviation can be determined using the LATCH SPT function block and AUT_MA_CAM_OFFSET(_VAX) of the CAM profile automat at the cutting position.

The cut positions for the next cut are calculated and uploaded cyclically to the PLC when using the MC_BR_CrossCutterControl function block. The output of the "CutMasterPosition" function block can be connected to "CutPosition" using MC_BR_RegMarkCapture002.

When a trigger event occurs, the RM LATCH captures the position setpoint of the transport axis (same as the master axis with MC_BR_CrossCutterControl, for example). The delay via DELAY SPT is necessary to establish the time difference between the received position setpoint and the actual transport axis (t_total must be set correctly)

The complete delay (LATCH+DELAY) is calculated as follows (negative means interpolation required):

The parameter ".SensorDelay" is signed. An unsigned multiple of 400 µs is used for DELAY SPT instance (with "*" marked "Compensation time" in picture) to reduce the incorrect calculation of interpolation (linear calculation inside LATCH). The rest will be used with negative sign for interpolation with LATCH_T_DELAY of the RM LATCH. (e.g. with sensor delay 50 µs ∆t = -1050 µs→ LATCH_T_DELAY= -250 µs, compensation time = 800 µs)

A delay of the position info has the same effect as an interpolation with the basis of a trigger signal from the registration mark sensor.