A correction is calculated every time a new "CutPosition" is specified on the function block input and corresponding position information is stored inside the FIFO buffer.

Otherwise, the value of "CutPosition" is ignored (since the ".DistanceToSensor" must still take place before a correction is permitted to be output).

If no FIFO buffer is used (e.g. if ".ProductLength" > ".DistanceToSensor"), then both the change to "CutPosition" as well as a new registration mark is used as the event for the calculation. Output only takes place, however, if both values are new and at least one registration mark was detected.

To handle update procedures with MC_BR_CrossCutterControl, for example, the corresponding ".ProductLength" is added to "CutPosition" internally to calculate the correction for the next product. This performs the necessary calculation for the next product, and the update procedure can take place with MC_BR_CrossCutterControl promptly in the cycle beforehand.

If the correction value calculation should be performed in the current interval, the option "AdvancedParameters.CorrectCurrentCycle" should be enabled. This should also be configured for MC_BR_CrossCutterControl, for example, or if the correction is performed using MC_Phasing (see Additional information).

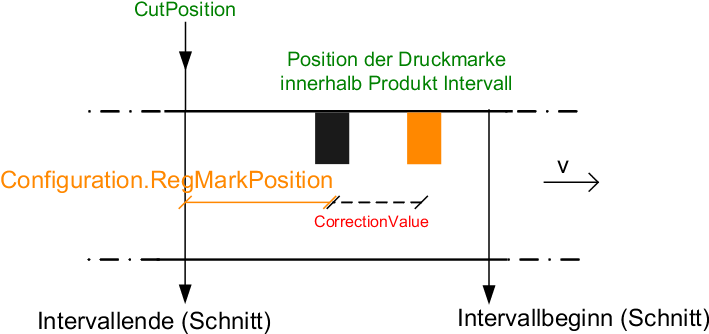

The correction is calculated using the following formula:

Limiting is then used according to the settings for "AdvancedParameters.CorrectionValueLimitXxx".

The following image illustrates how the different function block parameters affect how the output value for the "CorrectionValue" is calculated.

The value for "Configuration.RegMarkPosition" can also be set to 0 so that the cut will take place at the registration mark.