This setting is added to the basic mode.

For example, this mode can be used to keep a constant distance between the registration mark and the cutting position when the product length is variable. An "average length" can be defined for such products using "ProductParameters.Length".

In this case, an event must be specified for the interval start since a fixed master interval cannot be defined.

In principle, any readable ParID of a drive can be used as an event source ("TriggerInput.IntervalSourceParID").

"TriggerInput.IntervalLevel" and "TriggerInput.IntervalCompareMode" must be used to define the threshold and the comparison mode for the event.

The value of any INTEGER ParID that is used as the source for "TriggerInput.IntervalSourceParID" is not permitted to overflow.

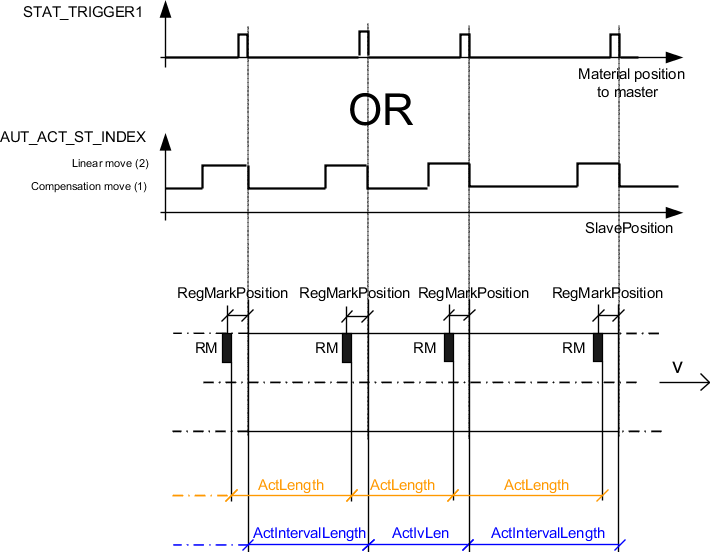

Examples of ParIDs as a source for "IntervalSourceParID"

•ACP10PAR_AUT_ACT_ST_INDEX (current state of the Cam Profile Automat)

•ACP10PAR_STAT_TRIGGER1 (status of the input Trigger 1 of the drive)

•ACP10PAR_STAT_TRIGGER2 (status of the input Trigger 2 of the drive)

•ACP10PAR_LOGIC_VALUE + Instance (output of a LOGIC SPT function block)

Examples of interval events

Fig.: Examples of interval events

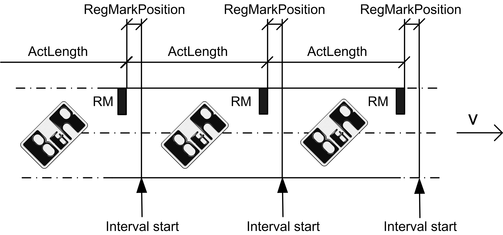

Example of "MasterInterval" ("Mode" without +mcINTERVAL_EVENT)

Fig.: Example of "MasterInterval" ("Mode" without +mcINTERVAL_EVENT)

The interval start is generated using the master position, "TriggerInput.MasterInterval" and "TriggerInput.IntervalLevel".