This function block is used to determine the absolute position ("ActPosition") of a registration mark within one product interval. From a position setpoint ("ProductParameters.RegMarkPosition") and the measured absolute position of the registration mark in the product interval ("ActPosition"), a "position error" results which is output to the "PositionError" output.

Requirements for use

•This function block can only be used on SG4 target system.

•This function block cannot be used with axes on a CAN bus.

•For transport axes with product intervals that can be changed, for example, a difference to the configured axis period will occur after positioning for a longer amount of time (position of MC_ReadActualPosition and the current position in the interval drift apart). The axis period is not synchronized to the product cycles/intervals. This offset can only be compensated by re-homing the axis with MC_Home!

•The axes whose references are specified under "Master" and "Axis" can only move in the positive direction.

•It is not permitted to home the specified axis while the function block is active.

•PLCopen axis states in which the function block is permitted to be enabled

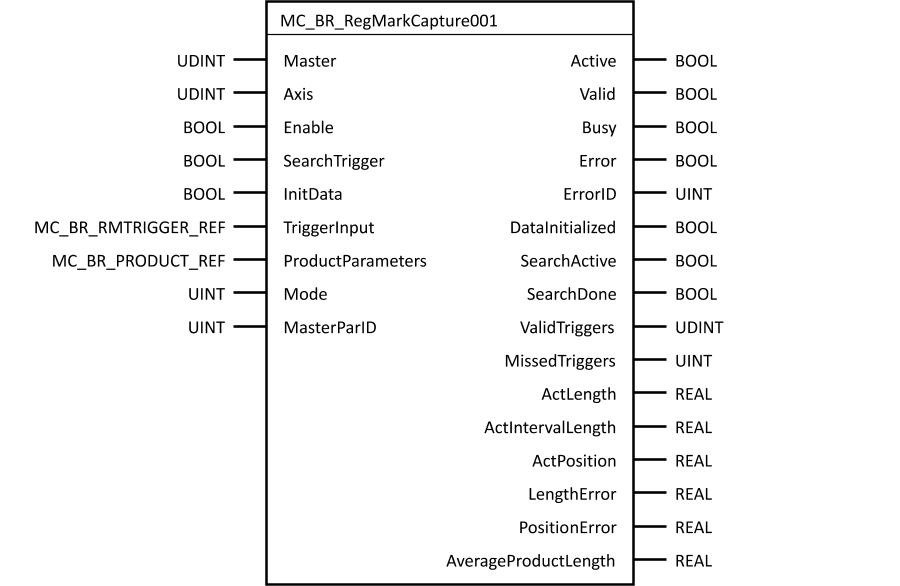

Function block

Parameter

I/O |

Parameter |

Data type |

Description |

IN |

Master |

UDINT |

Axis reference for the master interval reference (feed axis master) |

IN |

UDINT |

Axis reference for the axis on which registration mark detection is running (feed axis) |

|

IN |

BOOL |

Enables registration mark detection |

|

IN |

SearchTrigger |

BOOL |

Manually starts or reinitiates the search for a registration mark Note: This input is only evaluated if the following conditions are met: •"ProductParameters.SearchMode" must be enabled. •"ProductParameter.LengthChange" must be <> 0. The "SearchActive" output is set as soon as searching starts. The "SearchDone" output is set when a registration mark is found. If "Mode" = mcFIRST_TRIGGER, this input does not have to be used to search for the first registration mark. |

IN |

InitData |

BOOL |

Initializes input data on a rising edge (online change of function block input data) Note: When actively searching (indicated by output "SearchActive"), "InitData" can be set but the evaluation only takes place after the search is completed and the registration mark is found. |

IN |

TriggerInput |

MC_BR_RMTRIGGER_REF |

Description of the trigger input |

IN |

ProductParameters |

MC_BR_PRODUCT_REF |

Description of product and search parameters |

IN |

Mode |

UINT |

This operating mode can be used to define how the first registration mark is detected: mcACT_CFG ... 1 mcFIRST_TRIGGER ... 2 The behavior can be adapted to requirements by adding additional options: +mcINTERVAL_EVENT ... 16 +mcLENGTH_ONLY ... 32 +mcMANUAL_SEARCH ... 64 +mcCONTINUE_CONTROLLER_OFF ... 128 (V2.280 and later) |

IN |

MasterParID |

UINT |

This ParID is used instead of the position setpoint; 0…Use position setpoint Note: When using a value other than 0 (even if the position ParID), the PLCopen factor of the master axis is not applied to any of the parameters involving the master axis. |

OUT |

Active |

BOOL |

Registration mark detection running |

OUT |

Valid |

BOOL |

Outputs updated with new values from the drive Note: When using a mode with "+mcLENGTH_ONLY", a calculation can only be carried out again after invalid registration marks with two consecutive valid triggers. Note: This output is set to TRUE for one task class cycle and can therefore be used as a trigger for subsequent calculations. |

OUT |

Busy |

BOOL |

The function block is active and must continue to be called. |

OUT |

Error |

BOOL |

Error during execution |

OUT |

ErrorID |

UINT |

|

OUT |

DataInitialized |

BOOL |

Initializes input data on a rising edge of "InitData" |

OUT |

SearchActive |

BOOL |

Automatic/Manual registration mark search running Note: This output can also be set with a delay, but only at the next valid registration mark at the latest. |

OUT |

SearchDone |

BOOL |

Automatic/Manual registration mark search completed |

OUT |

ValidTriggers |

UDINT |

Number of valid trigger signals |

OUT |

MissedTriggers |

UINT |

Number of "undetected" triggers (set to 0 once a valid trigger signal is detected again) Note: This output is only incremented if an expected trigger event has not occurred. For example, any additional trigger signals that occur outside the window will not cause the output to be incremented. |

OUT |

ActLength |

REAL |

Current measured length (product length) [PLCopen units of "Axis"] |

OUT |

ActIntervalLength |

REAL |

Current measured distance between interval starts generated by an event ("IntervalSourceParID") [PLCopen units of "Axis"] Note: This output is only supplied in an operating mode with an interval event (+mcINTERVAL_EVENT) and can be used for diagnostic purposes (do the events for the interval start occur correctly, etc.). As a rule, the value of " ActIntervalLength " and "ActLength" should be as close to identical as possible. |

OUT |

ActPosition |

REAL |

Currently measured position of the registration mark within the product interval ["PLCopen units of "Axis"] Note: In an operating mode with +mcLENGTH_ONLY, the absolute position of the registration mark is output here. |

OUT |

LengthError |

REAL |

Deviation between the length setpoint ("ProductParameters.Length") and the measured length ("ActLength") [PLCopen units of "Axis"] Note: This value can be used for length compensation. |

OUT |

PositionError |

REAL |

Absolute deviation between expected position ("ProductParameters.RegMarkPosition") and measured position of the registration mark ("ActPosition") within an interval [PLCopen units of "Axis"] Note: This value can be used for position correction ("Offset" that must be corrected (± Product length / 2)). |

OUT |

AverageProductLength |

REAL |

Average value of the last 50 measured product lengths [PLCopen units of "Axis"] Note: This is reset when the function block is restarted. |

Table: Parameter MC_BR_RegMarkCapture001

MC_BR_RMTRIGGER_REF data type

Parameter |

Data type |

Description |

EventSourceParID |

UINT |

ACOPOS ParID as the event source (e.g. ACP10PAR_STAT_TRIGGER1 if registration mark sensor is connected to the drive's trigger 1 input) Note: A valid ACOPOS ParID must be specified here. |

PosSource |

USINT |

Position that should be stored on the drive ncS_SET ... Latches the position setpoint calculated on the drive ncS_ACT ... Latches the current position of the axis Note: ncS_ACT should be used to measure registration mark positions or other measurements for which the most accurate position possible is required. |

Edge |

USINT |

Edge selection for the trigger event: mcP_EDGE ... 0 (rising edge) mcN_EDGE ... 1 (falling edge) mcMIDDLE ... 5 (middle position between rising and falling edge) Note: mcMIDDLE is only possible if width monitoring is enabled ("MaxWidth" > 0). |

MinWidth |

REAL |

Minimum width of a valid trigger event [PLCopen units of axis] Note: Only values in the range 0 ≤ x ≤ MaxWidth are permitted. |

MaxWidth |

REAL |

Maximum width of a valid trigger event [PLCopen units of axis] Note: Only values ≥0 are permitted. 0 ... Width monitoring is disabled. |

WindowNegative |

REAL |

Window in which the valid trigger signal can occur before the expected position [PLCopen units of axis] Note: Only values ≥0 are permitted. |

WindowPositive |

REAL |

Window in which the valid trigger signal can occur after the expected position [PLCopen units of axis] Note: Only values ≥0 are permitted. |

MasterInterval |

REAL |

Master interval (duration) of a product cycle for determining the interval starting position of the axis [PLCopen units of master] Note: If there is no operating mode with interval event (+mcINTERVAL_EVENT), this parameter must be ≠ 0. If +mcINTERVAL_EVENT is used, however, this value is not used. |

IntervalSourceParID |

UINT |

ACOPOS ParID for detecting the start of an interval (significant event always recurring at the same point in time, e.g. Cam Profile Automat state, SPT function block, etc.) Note: If an operating mode with interval event (+mcINTERVAL_EVENT) is set, "IntervalSourceParID" must be a valid ACOPOS ParID. |

IntervalLevel |

REAL |

Functions dependent on the operating mode ("Mode"): - Without +mcINTERVAL_EVENT: The value is used as the starting position of the master interval. [PLCopen units of master] Example: The value of "LeadInMasterDistance" when using a MC_BR_AutoCamDwell function block for coupling in which the "StartOffset" ("LeadInSlaveDistance") is converted. - With +mcINTERVAL_EVENT: The value is used as a level for detecting the event from "IntervalSourceParID". Examples: 3 (entry into state 3 of the cam automat) with "IntervalSourceParID" = ACP10PAR_AUT_ACT_ST_INDEX 8 (trigger input 1 active) with "IntervalSourceParID" = ACP10PAR_STAT_TRIGGER1 1 (output of function block LOGIC SPT active) with "IntervalSourceParID" = ACP10PAR_LOGIC_VALUE |

IntervalCompareMode |

UINT |

Mode in reference to the "IntervalLevel" parameter in order to determine the type of signal generation (threshold value). mcGREATER ... 4 mcEQUAL ... 2 mcUNEQUAL ... 5 mcSMALLER ... 1 mcGE ... 6 mcSE ... 3 Note: "IntervalCompareMode" is only taken into account if an operating mode with interval event (+mcINTERVAL_EVENT) is set. |

SensorDelay |

DINT |

Registration mark sensor delay [µs] If the sensor's delay time is known, then the drive is able to correct the resulting position deviation. 0 … Registration mark sensor delay not taken into account Note: The delay time can be taken from the manufacturer's data sheet and is usually specified as a negative value. |

DisableWidthEvaluationAtStart |

BOOL |

Ignore width monitoring if the function block is enabled on the high level of the trigger signal 0 ... Perform width monitoring 1 ... Do not perform width monitoring (reject trigger) Note: Only applies if width monitoring is active (MinWidth > 0). |

MC_BR_PRODUCT_REF data type

Parameter |

Data type |

Description |

Length |

REAL |

Product length setpoint (user setting) [PLCopen units of axis] Note: Only values >0 are permitted. |

LengthChange |

REAL |

If the registration mark is no longer in the trigger window (see "SearchMode" and "MissedTriggerCount"), the window is not incremented by the value of the "Length" input, but by the value of "Length" + "LengthChange" instead. [PLCopen units of axis] Note: "LengthChange" can also be negative. |

LengthTolerance |

REAL |

Average deviation of the product length in percentage Note: This value is required for internal function block logic and should be 5% to 10%. The value "0" should not be used because it could cause valid trigger events to be rejected. |

StartOffset |

REAL |

Offset of the cut/seal axis at the start of the interval (start position of the seal/cut axis not equal to interval starting position) [PLCopen units of axis] Sealing example: Material should be protected against the effects of heating at a standstill. Note: Only used to calculate the first registration mark position when "Mode" = mcACT_CFG. |

RegMarkPosition |

REAL |

Position setpoint of the registration mark in the product interval based on the start of the interval (user setting) [PLCopen units of axis] |

DistanceToSensor |

REAL |

Distance between the cut/seal position and the registration mark sensor [PLCopen units of axis] Note: Only used to calculate the first registration mark position when "Mode" = mcACT_CFG. Only values > 0 are permitted. |

SearchMode |

UINT |

Disables/Enables automatic/manual registration mark search mcOFF...Automatic and manual searching for the registration mark is disabled. mcON...Automatic or manual searching for the registration mark is enabled. Note: If "SearchMode" = mcOFF, "MissedTriggerCount" must be set to 0. If searching is enabled ("SearchMode" = mcON), "LengthChange" must be ≠ 0. |

MissedTriggerCount |

UINT |

Number of consecutively missing trigger pulses after which automatic registration mark searching (with "LengthChange") should begin Note: If "Mode" = +mcMANUAL_SEARCH, this parameter is not evaluated. |

Topics in this section: