In the following example, the axis on which the registration mark controller is running is a slave axis. This means that its motion is performed using a coupling function block (e.g. MC_GearIn, MC_CamIn, MC_BR_AutControl, etc).

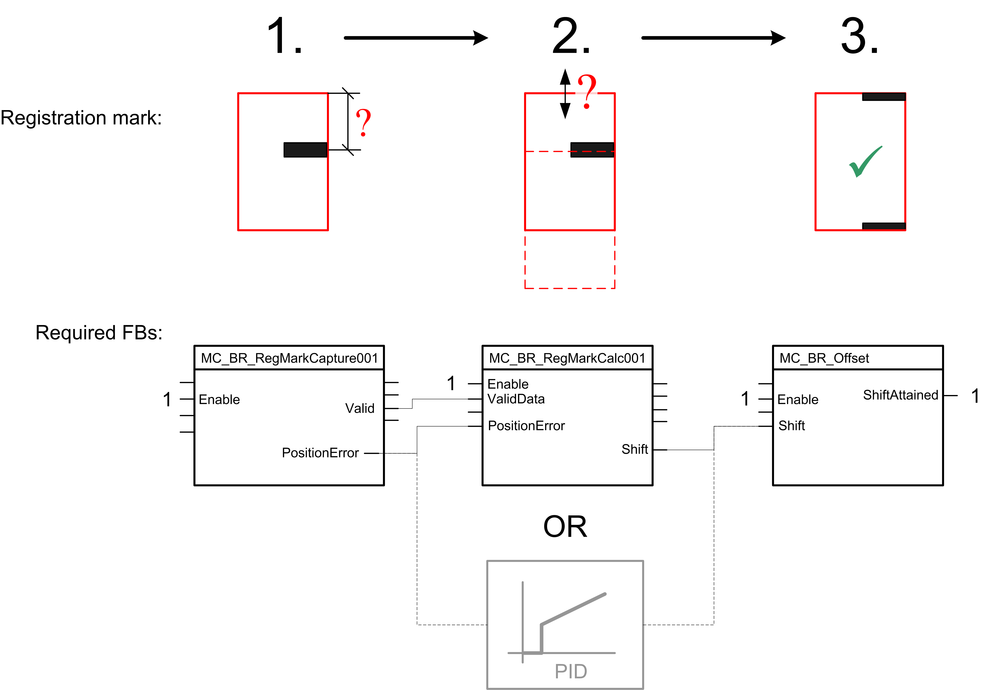

Fig.: Example of a possible application configuration

•The function block MC_BR_RegMarkCalc001 is used to determine the actual position of the registration mark within a product interval. This value ("ActPosition") is compared with the position setpoint of the registration mark ("ProductParameters.RegMarkPosition"). A deviation between the two values equals an absolute position error within a product interval and is output to the "PositionError" output. This position error must be compensated for so that the next cut/seal/etc. takes place at the correct position.

•The MC_BR_RegMarkCalc001 function block is supplied with the value of the "PositionError" output and converts this value to a shifting distance that is output (possibly filtered and restricted by other limitations) on the "Shift" output.

A simple P controller can also be used. In this case, the proportional gain should be set to <1.

•A shift on the slave side is implemented based on the "Shift" distance using the MC_BR_Offset function block (e.g. on the transport axis). As a result, the position correction is applied to the material, the position error is corrected and the product is cut/sealed/etc. as desired.

All 3 function blocks together create a closed control loop.