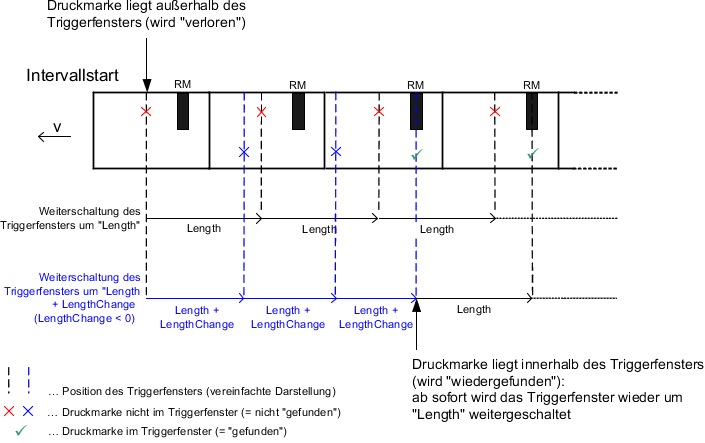

A registration mark is considered "lost" when a valid trigger signal cannot be detected within a defined window.

The trigger window is normally moved forward by the distance "Length" (product length) to find the next registration mark. The trigger window is therefore located at the same position in every subsequent product interval (based on the interval start).

If the registration mark is shifted outside of the trigger window (e.g. by a change in material), then it will no longer be detected by the function block (see the following figure - "Stepping the trigger window forward by 'Length'").

If a registration mark is "lost", then the value on the "MissedTriggers" output is incremented.

In order to "find" a registration mark again, the distance used for shifting the trigger window forward must be extended or shortened ("Length + LengthChange"). In each subsequent product interval, the position of the trigger window is shifted according to the interval start (the trigger window "drifts" closer to the registration mark, the registration mark is "searched for") until the registration mark is located within the trigger window (the registration mark is "found").

From this point on, the trigger window is shifted forward again by the "Length" distance (see the following figure - "Stepping the trigger window forward by 'Length + LengthChange'").

"MissedTriggers" is reset to 0 and "ValidTriggers" is incremented at each valid registration mark.

A jump occurs on the "PositionError" output after a new reference is found.

Fig.: Retrieving a lost registration mark

•If there is any slack on the transport axis, then the transport axis has already reached the expected position. The actual position of the registration mark remains behind the expected position depending on the amount of slack. In this case, the registration mark can be "recovered" more quickly if the distance is shortened ("LengthChange" < 0).

•A satisfactory result of registration mark control is therefore only possible by minimizing as many disturbance factors in the machine as possible (slack, unintended material movements, incorrect measurement of the registration mark sensor, etc.). These measures also accelerate the search for "lost" registration marks.

•The transport axis must be moved when searching for a registration mark. A registration mark cannot be found when the transport axis is at a standstill!

•When searching for a registration mark, all outputs except "SearchActive" are set to 0. "Active", "Busy", "Error", "ErrorID" are exceptions to this. They conform to PLCopen behavior.

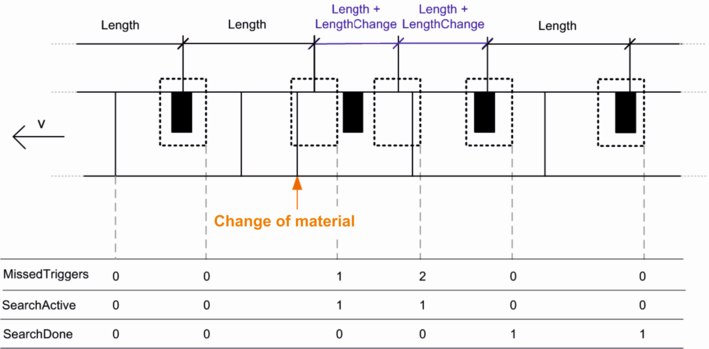

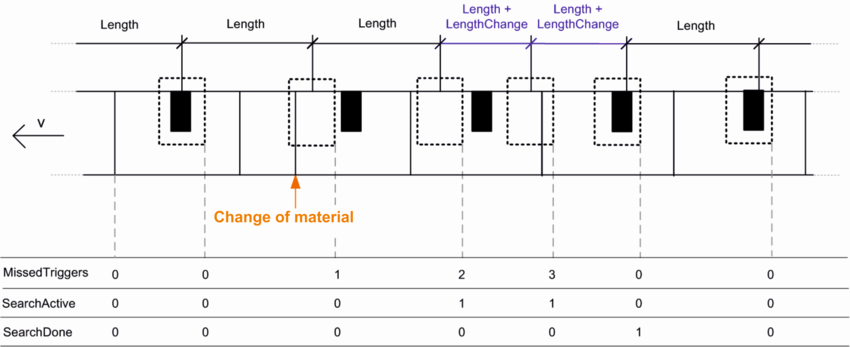

The function block can be configured in such a way that the registration mark is automatically searched for again in the event of a material change, for example, if no valid registration mark is detected within the set trigger window ("ProductParameters.SearchMode" = mcON and "ProductParameters.LengthChange" ≠ 0).

The automatic search can either be started immediately after the first missing registration mark ("MissedTriggers" > 0) or after a certain number of consecutive missing registration marks ("MissedTriggers" ≥ "ProductParameters.MissedTriggerCount").

"ProductParameters.MissedTriggerCount" = 0 or 1 (immediate search)

Trigger windows are displayed as dashed boxes.

Fig.: "ProductParameters.MissedTriggerCount" 1

"ProductParameters.MissedTriggerCount" = 2 (delayed search)

Trigger windows are displayed as dashed boxes.

Fig.: "ProductParameters.MissedTriggerCount" 2

Information:

Contamination of the registration mark sensor or material (dirt, etc.) can cause registration marks to be detected sporadically or not detected at all (even though the registration marks are within the trigger window). If searching has already started at the first undetected registration mark in this case, there will be a sharp increase in the number of search procedures. Many of these search procedures can be avoided if several consecutive missing triggers (i.e. undetected registration marks) are awaited first.