This function block is intended for registration mark detection and correction together with MC_BR_CrossCutterControl.

For general term definitions, see General information under "Registration mark control".

A correction to the coupling between a cross cutter axis (slave) and a transport axis (master) should only be made to the slave axis by adjusting the product length ("ProductLengthCorrection" parameter from MC_BR_CrossCutterControl) or via a phase shift (MC_Phasing, MC_BR_Phasing). A correction on the slave side, e.g. with MC_BR_Offset, will result in the cut position being shifted.

Correcting the transport axis is not possible since the material speed cannot be adjusted, for example. (depends on the device configuration).

A desired set cut position is calculated using the detected registration mark (+"Configuration.DistanceToSensor") and the user setting "Configuration.RegMarkPosition" and stored in an internal FIFO buffer.

If the calculated cutting position setpoint and the value on the "CutPosition" input are in the same product interval, then a correction value is calculated and output to the "CorrectionValue" output.

The MC_TouchProbe or MC_BR_TouchProbe function block can be used to capture the position of the registration mark for basic applications or if this function block cannot be used due to certain limitations.

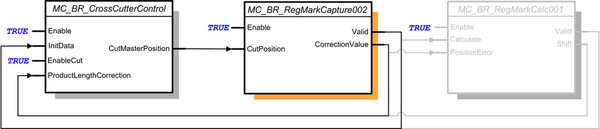

Example of a recommended user configuration

The use of MC_BR_RegMarkCalc001 is optional. The outputs of MC_BR_RegMarkCapture002 can also be directly linked to the inputs of MC_BR_CrossCutterControl.

Registration mark control set up in this manner prevents the registration mark from drifting from a specified position on the product (at constant cut length).

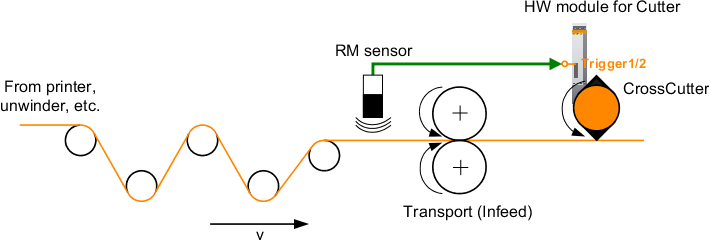

Recommended hardware configuration

The registration mark sensor (RM sensor) must be wired to a trigger input on the cross cutter axis whose axis reference is specified on the "Axis" input.

Caution!

Dancer control is not permitted to take place between the sensor and the cross cutter axis; otherwise, the captured position and the position of the transport axis will no longer match up!