This function block has the following functions:

•Execution of a cam coupling (like MC_CamIn).

•The 1:1 cam predefined on the drive can be used (mcLINEAR_CAM).

•A compensation phase can be defined between the cams. This results in the following movement sequence: Cam – Compensation – Cam – Compensation – ...

•A lead-in or lead-out movement can be started while the master axis is running. The slave axis does not move before the lead-in or after the lead-out movement.

•A compensation distance can be specified for the lead-in and lead-out movement.

•Gauge factors are specified for the cam and slave interval; the compensation distance between cams is calculated automatically.

•A "CamTime" can be specified instead of the master factor to define the duration of the cam.

Setting the "Enable" input switches the axis to the PLCopen Synchronized Motion state and transfers all necessary parameters to the respective drives.

The "Active" output is set after the parameters have been transferred. In this way, the coupling can be started when the "LeadInSignal" input is set or the ParID specified for "LeadInParID" changes from 0 to a value ≠ 0.

The movement can be stopped when the "LeadOutSignal" input is set or the ParID specified for "LeadOutParID" changes from 0 to a value ≠ 0.

If the "Enable" input is set to FALSE, the movement is stopped and the axis changes to the PLCopen axis state Standstill.

The cam, compensation or lead-in movement can be shifted on the master side with the MC_Phasing or MC_BR_Phasing function block. An offset shift on the slave side can be implemented using the MC_BR_Offset function block.

Basic function

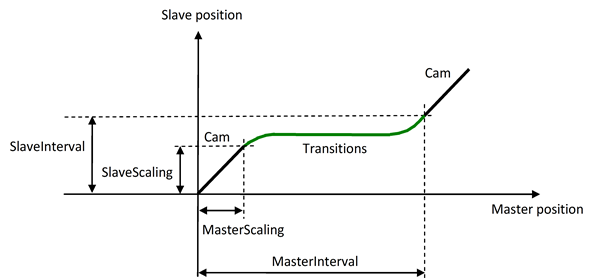

After the lead-in signal, the slave axis performs a cam movement followed by an automatically calculated transition phase.

The cam listed in the "CamTableID" can be scaled using the "MasterScaling" and "SlaveScaling" inputs.

The interval at which the cam should be repeated can be specified for the master and slave axis. This movement is repeated until the "LeadOutSignal" input is set or the ParID specified for "LeadOutParID" has a value ≠ 0.