This function block starts a cam link between the master and slave axis. It is possible to configure a cam followed by a standstill.

Requirements for use

•Function block name for SG3/SGC target systems MC_037BR_CamDwell

•This coupling can only be started if the master axis is moving in the positive direction!

•It is not permitted to home the specified axis while the function block is active.

•Axis states of the slave axis in which this function block can be used:

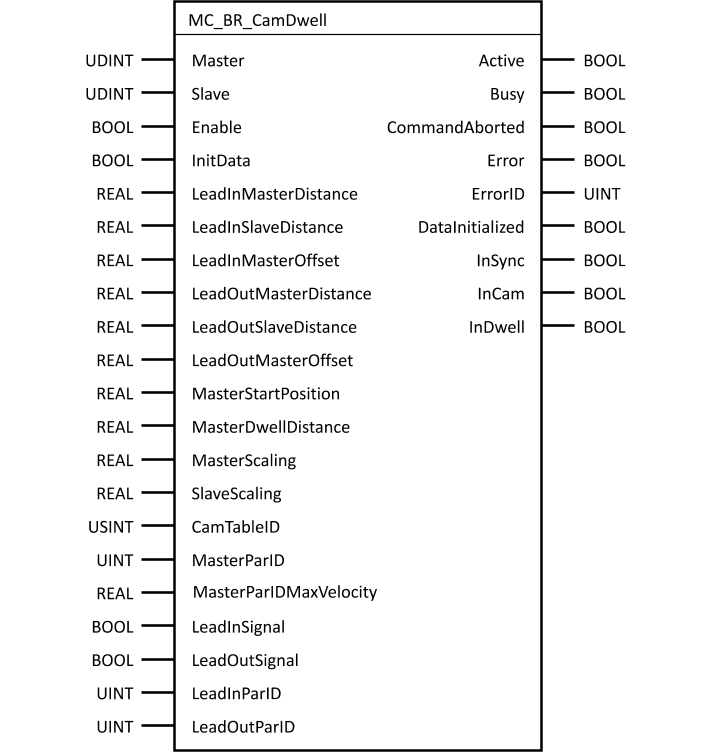

Function block

Parameter

I/O |

Parameter |

Data type |

Description |

IN |

Master |

UDINT |

Master axis reference |

IN |

Slave |

UDINT |

Slave axis reference |

IN |

BOOL |

The function block is active as long as this input is set. |

|

IN |

InitData |

BOOL |

Initializes input data on a rising edge (online change of function block input data) |

IN |

LeadInMasterDistance |

REAL |

Compensation distance of master axis for the lead-in movement [PLCopen units of master] |

IN |

LeadInSlaveDistance |

REAL |

Compensation distance of slave axis for the lead-in movement [PLCopen units of slave] |

IN |

LeadInMasterOffset |

REAL |

Offset on the master side within the cam. The compensating movement for the lead-in movement leads to this position [PLCopen units of master] |

IN |

LeadOutMasterDistance |

REAL |

Compensation distance of master axis for the lead-out movement [PLCopen units of master] |

IN |

LeadOutSlaveDistance |

REAL |

Compensation distance of slave axis for the lead-out movement [PLCopen units of slave] |

IN |

LeadOutMasterOffset |

REAL |

Offset on the master side within the cam. The compensating movement for the lead-out movement starts at this position [PLCopen units of master] |

IN |

MasterStartPosition |

REAL |

Position within the period of the master axis or absolute position on a non-periodic master axis for beginning the cam [PLCopen units of master] Note: If "MasterParID" is used, no new value is calculated internally when restarting. This means that if the master position can overflow from the positive to the negative range of values, this value should be recalculated before each start. Otherwise, it is possible that re-coupling will not take place until the positive master start position is reached. |

IN |

MasterDwellDistance |

REAL |

Length for an optimal standstill phase of the slave axis on the master side [PLCopen units of master]. If the lead-out speed for the cam ≠ 0, a speed jump will occur. If the value is set to 0, the cam is immediately started again. A speed jump will then not occur if the lead-out speed of the cam is ≠ 0. |

IN |

MasterScaling |

REAL |

Factor for the master profile |

IN |

SlaveScaling |

REAL |

Factor for the slave profile |

IN |

CamTableID |

USINT |

ID number of the cam, output from MC_CamTableSelect Predefined 1:1 cam (master and slave length = 1) |

IN |

MasterParID |

UINT |

This ParID is used instead of the position setpoint; 0…Use position setpoint Note: When using a value other than 0 (even if the position ParID), the PLCopen factor of the master axis is not applied to any of the parameters involving the master axis. |

IN |

MasterParIDMaxVelocity |

REAL |

Prior to V2.290: Maximum speed of the master ParID value, only evaluated if the MasterParID is used

V2.290 and higher: If this parameter is "0.0", the current velocity of the master axis is used If a value is specified for "MasterParID": Maximum velocity of the master ParID value If a value is not specified for "MasterParID": Maximum velocity of the master axis [PLCopen units of master/s] Note: This value is used to calculate the compensating movement for coupling, changing the gear ratio or cams as well as between the cutting areas (depending on the function). This parameter has a considerable effect on the occurrence of ACOPOS error 37113: "Cam compensation gear: Limit values exceeded". No value specified: A master speed that changes or a parameter update via "InitData" or "Execute" can result in different, automatically calculated motion profiles. Value specified: Specifying the maximum speed value of the master axis that is achieved while coupled to the slave axis results in a motion profile that is always automatically calculated the same. |

IN |

LeadInSignal |

BOOL |

Signal from the controller to start the lead-in movement |

IN |

LeadOutSignal |

BOOL |

Signal from the controller to start the lead-out movement |

IN |

LeadInParID |

UINT |

ParID that can be used by the drive to start the lead-in movement when the value changes from 0 to a value ≠ 0 |

IN |

LeadOutParID |

UINT |

ParID that can be used by the drive to start the lead-in movement when the value changes from 0 to a value ≠ 0 |

OUT |

Active |

BOOL |

Function block active, possible to execute movements Function block waiting for a lead-in signal |

OUT |

Busy |

BOOL |

The function block is active and must continue to be called. |

OUT |

CommandAborted |

BOOL |

Function block aborted by another function block |

OUT |

Error |

BOOL |

Error during execution |

OUT |

ErrorID |

UINT |

|

OUT |

DataInitialized |

BOOL |

Changes to function block inputs initialized |

OUT |

InSync |

BOOL |

Synchronous couple to master achieved. Reset as soon as the lead-out movement is started. |

OUT |

InCam |

BOOL |

Coupling in cam range |

OUT |

InDwell |

BOOL |

Coupling in standstill range |

Table: Parameter MC_BR_CamDwell

Topics in this section: